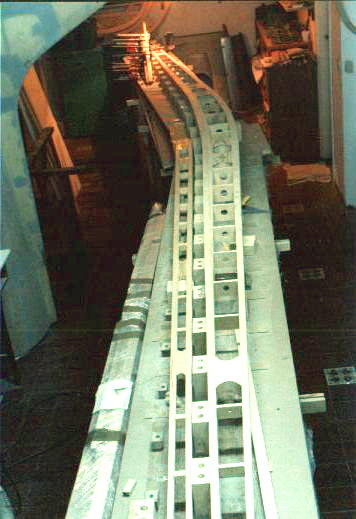

This is

the way we used the table.A lot of clamping , isn't it?

The upper

boom is under gluing up while the lower one is finished.

It's not

such a difficult work when you have a perfect table and you work under

18° C if you're using Aerolite; Clamping time is very short and

you risk not to do a bad gluing.

The completion

of the jig took 80 hours of working and checking time.(we checked everything

three times).Preparation of the wood for the lamination was well made

, controlling the grain , scarfing the wood, drawing the dimension

both in the jig and in the future boom, and drawing also all the references

for a fast gluing up.

After this

kind of preparation, we found the real gluing easier than the

laminations for the frames. We glued one lamination per time, starting

obviously with two layers in the lower spar boom since there is one

joint between them.

With the watch in the hand and in 4 people

we firstly took 8 minutes to clamp everything using masked blocks

between the wood and the head of the clamp to protect the spruce. Then

getting experienced in one week-end in two we glued all the upper spar

boom, and it took us about 7 minutes per lamination. The system that

proved to be better was to start from one side to clamp in position

the side spruce layer, then joining the scarf with the middle

layer, clamp everything, and then the last one. In this way ,with good

references drawn down, your clamping time is very low, and the use of

Aerolite is no longer a problem.

![]()

![]()